Food Safety Principles

We are working hard to provide safe products at all stages including product development, manufacture, distribution, and sales according to the Orion Food Safety System.

-

R&D

- Selecting safe raw materials;

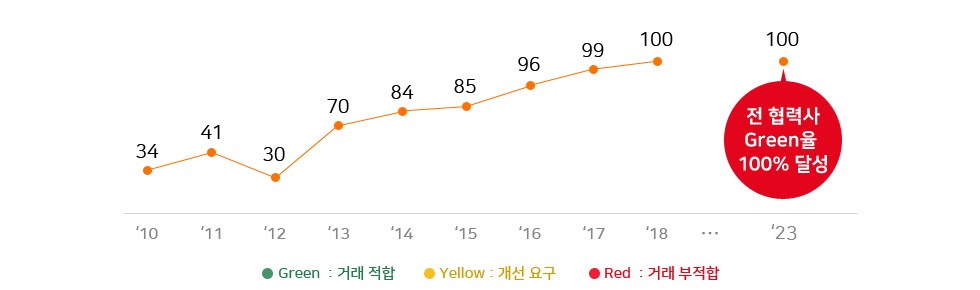

- Inspection of suppliers & supporting them to make improvement

- Prevention of risk factors in advance

-

Production

- Inspection of production locations (GQAS)

- Earning food safety certificates

- Assessment on risk factors in finished products

-

Distribution and Sales

- Safety control of product distribution;

- Collection of distributed products for inspections

- Provision of accurate information

Food Safety Prevention

Orion conducts thorough analysis and monitoring throughout the entire process, from the raw material stage to the point where products are sold to consumers, in order to proactively prevent food safety incidents. We are committed to providing safe food to consumers through a variety of systems designed to ensure their safety.

To prevent food safety incidents, Orion analyzes and monitors every step of the process, from raw materials to product sale. We strive to ensure food safety through a variety of systems and protocols.

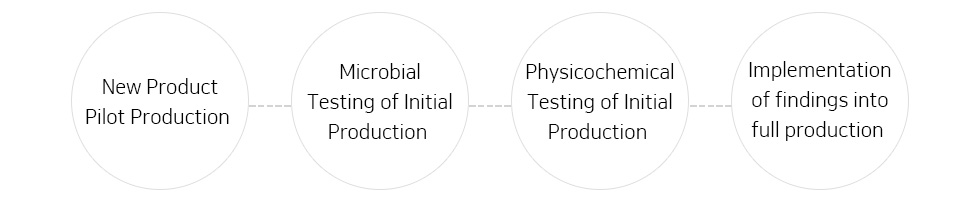

In order to ensure compliance with legal standards and internal management criteria, as well as their overall safety, new products produced through hygienic quality verification are subject to pre-launch inspections.

Since 2012, we have established and implemented an annual food safety inspection plan to proactively prevent food safety incidents. This plan enables us to identify and mitigate potential hazards from raw materials to finished products, ensuring safe products to consumers.

Food Safety Inspection

We are establishing a preliminary risk prevention system through a full-scale in-house food safety inspection system. The goal of the Global Quality Assurance System (GQSA) is to increase the safety of all production locations by checking and making improvements to our food safety status. We develop food safety auditors at all global locations with vast experience in the field and expertise to inspect the food safety of our entire factories. Every year, we identify areas of improvement based on inspections and increase our food safety levels by addressing those issues. The Quality Safety Team uses a food safety calendar in which we schedule the checking of different risk factors and securing of the safety of raw materials and Orion product distribution. In 2021, we've performed 1,403 analyses in microorganisms & physicochemicals.

Food Safety Certificate Status

Our factories in Korea and abroad strictly maintain food safety certificates that meet international standards.

| Countries | No. of factories | Certificates |

|---|---|---|

| Korea | 2 | FSSC22000, HACCP |

| China | 4 | FSSC22000, HACCP |

| Vietnam | 2 | FSSC22000, HALAL, HACCP |

| Russia | 2 | FSSC22000 |

Hygiene and Safety Enhancement Activities

Orion is engaged in various initiatives to provide consumers with safer products through enhanced hygiene and safety measures. We have achieved HACCP certification across all production lines and FSSC 22000 certification. Additionally, we participate in the AIB Global Audit Program, where our trained internal auditors perform self-inspections of all production lines to strengthen hygiene and safety further.

We regularly provide hygiene support to our raw material suppliers and conduct hygiene and safety management training for our partners. This initiative aims to improve our suppliers' hygiene and safety standards.

-

< Support for improving hygiene and safety on-site >

-

< Training on Hygiene and Safety Management for Partners >

In order to enhance our food safety management through digital transformation, Orion is taking part in a government-supported initiative by the Ministry of Food and Drug Safety in 2024 to establish a Smart HACCP system

-

< Government Business Operation Organization Chart >

-

< Smart HACCP Logo >